| |

|

|

|

|---|---|---|---|

| |

|

|

|

The innovative idea of a photonic crystal structure was first formulated by our research team as a concept. However, it has not been tested in a microwave field homogenization system for a commercial food preparation application (in a commercial microwave oven). As a result, we started the research from a TRL2 level. A static photonic crystal (PCY) homogenizer (MHD) has been designed and built, a compact structure (with no moving parts, unlike conventional microwave oven homogenizers) that can be easily inserted and extracted from an commercial microwave oven. This structure (MHD-PCY) has been designed to be both a support for the food introduced into the oven for processing and also a microwave field homogenizer inside oven, thereby ensuring a uniform heat treatment of the food. Microwave oven tests have been carried out with the new homogenization system by determining the microwave field distribution in the oven cavity. Based on the obtained results, we performed corrections / modifications in the MHD-PCY structure. Finally, two standard food recipes were prepared and the compliance of the prepared product was verified in accordance with the European standard EN 60705/2012 ("Household microwave ovens - methods for measuring performance"). After the project’s implementation, a technological maturity level of TRL4 has been reached. The resultant product, an experimental model of a homogenizer (MHC) with a stationary photonic crystal (PCY) adapted for a commercial microwave oven, is a laboratory-validated prototype. The test results confirmed that the product made from the individual components functions very well as a whole device, making up a microwave field homogenization system that improves the processing (cooking) of food in household microwave ovens. |

|||||||||

|---|---|---|---|---|---|---|---|---|---|

|

|||||||||

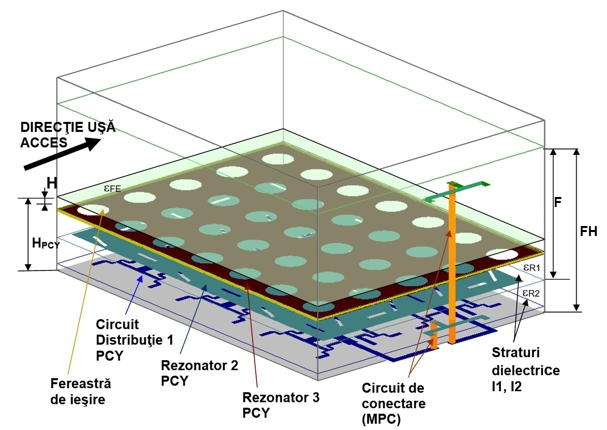

Obtained results Our selected static photonic crystal structure (PCY), consisting of a set of resonators arranged periodically with a network constant A (mm) in a given volume, has three main layers, four secondary layers and a connection circuit (MPC) at the microwave output slots existing in the commercial microwave oven. |

|||||||||

|

|||||||||

Figure 1. The static photonic crystal design (PCY) configuration and its location in |

|||||||||

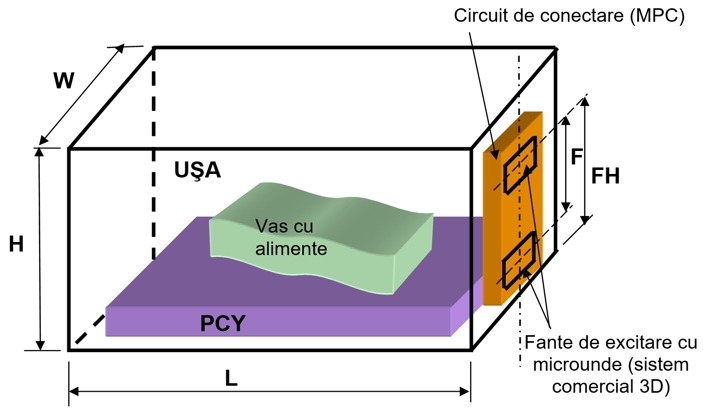

| The photonic crystal homogenization assembly (MHD-PCY) provides a selective power transfer between the microwave input of the classic microwave oven (with two inlet slots) and the crystal exit, located in a plane perpendicular to the inlet plane, and a homogenization of the power density of the transmitted wave. |

|||||||||

|

|||||||||

Figure 2. 3D configuration of the microwave enclosure with the PCY structure inserted into the treatment chamber. |

|||||||||

|

|||||||||

Figure 3. Photonic Crystal Homogenization Assembly (MHD-PCY): Positioning (MHD-PCY) in the commercial microwave oven |

|||||||||

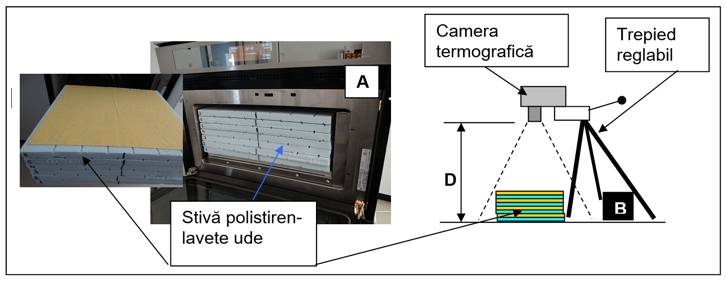

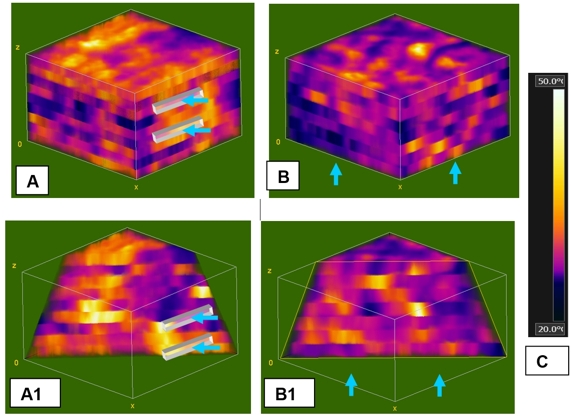

The method for characterizing the power density distribution in the volume of a microwave oven by using an infrared (IR) sensitive camera is based on the thermal imaging of a thermographic transducer, which in our case is a dielectric multilayer containing alternatively uniformly distributed microwave sensitive heated layers. The transducer is exposed to the microwave power signal only once, then, in a short time, the absorbent layers are photographed successively in the IR domain. Between temperature and power density we found a linear dependence. |

|||||||||

|

|||||||||

Figure 4. IR method derived from the thermographic method: |

|||||||||

|

|||||||||

Figure 5. Volume distribution of the temperature: |

|||||||||

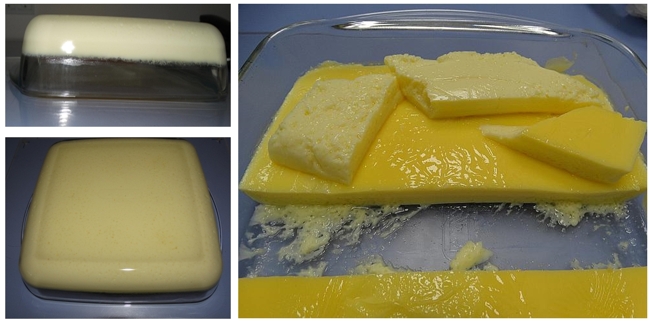

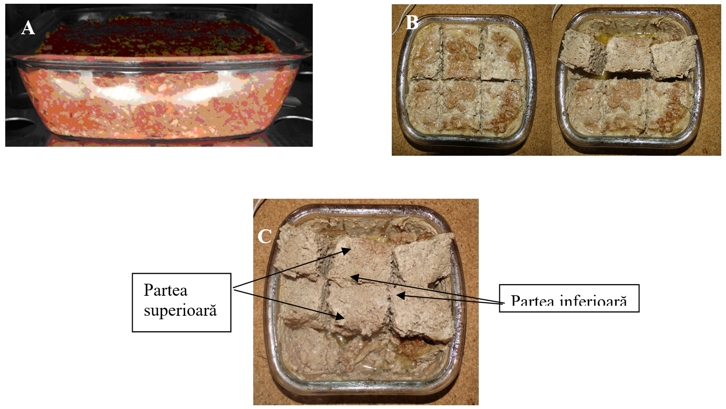

The thermal treatment homogeneity testing was performed for two situations: the “egg cream” recipe and the recipe for “meat loaf” (European Standard EN 60705, Household microwave ovens - IEC 60705: 2010 modified, May 2012 ). |

|||||||||

|

|||||||||

|

|||||||||

Figure 7. Meat loaf roll prepared in the commercial microwave oven using the MHD-PCY |

|||||||||

Dissemination |

|||||||||